Graphite based Anode Active Material (AAM) is the largest component by weight of lithium ion batteries and relies on ultra-high purity (99.95%) graphite anode precursor material. Furthermore, battery applications require low levels (less than 50 parts per million, ppm) of impurities such as Fe, Cr, Ni, Si, Ca, SO4, etc. to ensure battery performance (life) and safety.

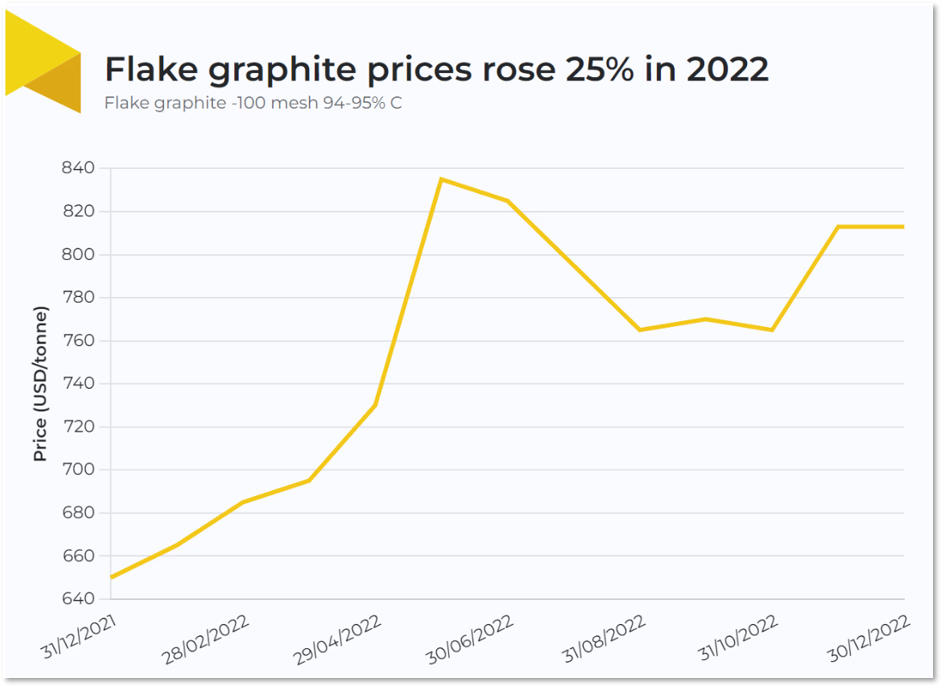

With the rapid growth of ex-China battery markets, implementation of Critical Raw Material Act in Europe, and Inflation Reduction Act in US, it is paramount to have a low cost, proven, and environmentally superior refining process to produce battery grade graphite. Recognizing this market opportunity, Volt has developed a patent pending (US patent application number 63/696,244) low cost and hydrofluoric acid (HF) fee process which has been proven during bench scale studies.

Selection of a site for a chemical plant is a complex process involving assessment of various factors such as the total cost of production; access to utilities, skilled labour, financial incentives, and renewable power; ease of permitting; connectivity via road, port, and rail; etc. Volt has identified a suitable 33-acre industrial site in Tuscaloosa, Alabama, US for locating the planned natural graphite refinery and processing plant. The site is in the Tuscaloosa County Airport Industrial Park with access to water system, sanitary sewer system, electrical infrastructure, and transportation infrastructure.

Deutsch

Deutsch English

English